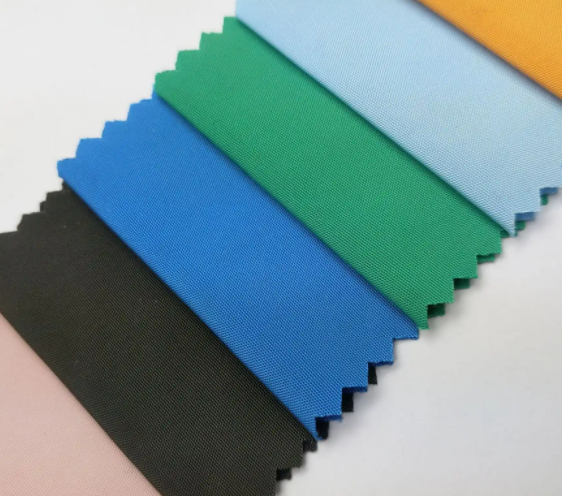

Common Fabric Processing Techniques

Release time: 2025-07-07

Common Fabric Processing Techniques

Fabric post-processing refers to a series of processing steps carried out on fabrics after weaving to enhance their performance, texture, appearance, and other aspects. Mainly improving the feel, appearance, or functionality of fabrics, it is divided into physical finishing and chemical finishing.

Physical organization

Stabilize fabric size through high temperature and tension, improve shrinkage rate, and adjust fabric width and surface flatness (such as used for shirt fabrics and suit fabrics)

Stretching and shaping

Calendering/embossing

Using the pressure and temperature of the rolling mill to make the surface of the fabric smooth (calendering) or form patterns (embossing), improving glossiness and texture (commonly seen in curtain fabrics and fashion fabrics).

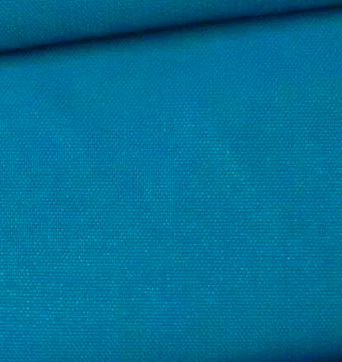

Fuzzing/sanding

By mechanical friction, fluff is generated on the surface of the fabric to increase softness and warmth (such as flannel and sweatshirt fabrics). By mechanical friction, fluff is generated on the surface of the fabric to increase softness and warmth (such as flannel and sweatshirt fabrics)

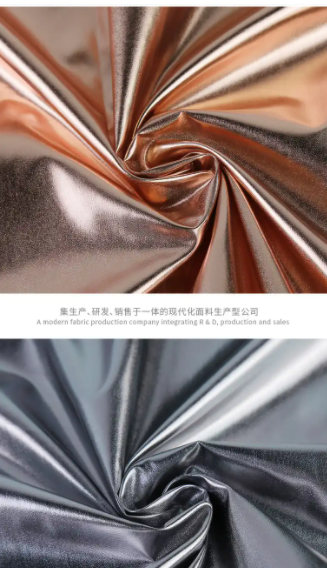

Hot stamping/silver stamping

Transfer metal foil to the surface of the fabric through high temperature to form decorative patterns and increase the sense of luxury (often used for stage costumes and festival fabrics)

chemical finishing

Using softeners to reduce friction between fibers and make the fabric feel smoother (such as pure cotton T-shirt fabric, silk fabric)

stiff finish

By sizing or resin treatment, make the fabric firmer (such as shirt collar lining, suit fabric)

crease-resist finish

Using chemical agents such as resin to reduce fabric wrinkles and improve ironing resistance (such as business shirt fabrics)

Suzhou-Jiangsu-China

Suzhou-Jiangsu-China +0512-63373373

+0512-63373373 info@shangyutex.com

info@shangyutex.com