Post finishing process, fabric feel and functionality

Release time: 2025-09-16

Post finishing process

Fabric feel and functionality

Do you know

The finishing process - the processing step after the fabric is woven - is the core that gives it a tactile feel, appearance, and special functions. Common post finishing processes include sanding, calendering, coating, anti-static finishing, and non ironing finishing.

Let's take a look at these post-processing techniques

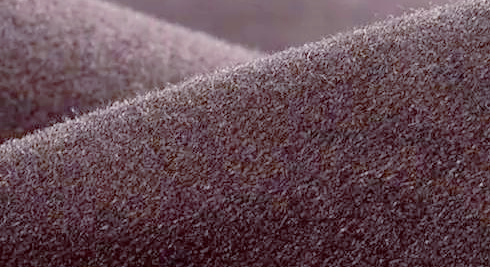

sanding(brushed )

This is brushed fabric

Rub the surface of the fabric with sandpaper or a sanding machine to pull out short fluff. Soft and warm to the touch, with a suede texture and a soft luster. Four piece set with brushed hair, winter shirt

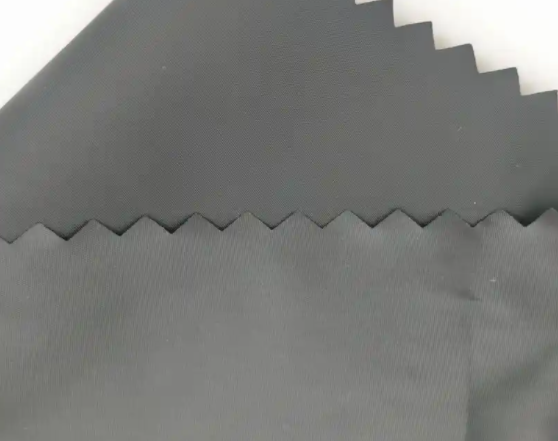

calendering

The fabric is flattened by high-temperature and high-pressure rollers to flatten the surface fibers. Smooth and glossy surface, firm and firm feel, not easily wrinkled polyester cotton shirt and dress fabric

coating

Coat the surface of the fabric with a layer of polymer (such as PU, PVC). Windproof, waterproof, and anti drilling velvet, enhancing the wear resistance of jackets, down jackets, and raincoats

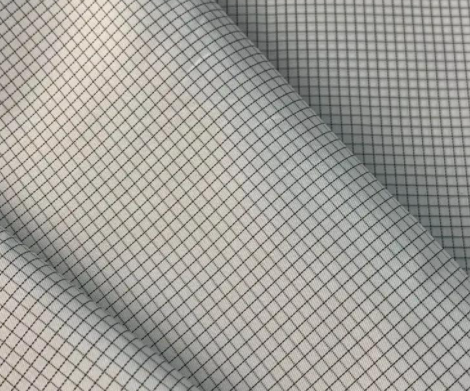

Antistatic finishing

Dip and roll antistatic agents to form a conductive film on the surface of fibers. Reduce static electricity accumulation, avoid adsorbing dust, close fitting synthetic shirts, professional clothing, and electronic factory work clothes

easy care

Treat cotton fibers with resin crosslinking agents to fix their molecular structure. Not easy to wrinkle after washing, no need for ironing, good shape retention for business pure cotton shirts and workwear

Suzhou-Jiangsu-China

Suzhou-Jiangsu-China +0512-63373373

+0512-63373373 info@shangyutex.com

info@shangyutex.com